iSebe loLawulo lweZixhobo, iSinopec Yizheng Chemical Fiber Co., Ltd. 211900

Abstract: Eli phepha lihlalutya izizathu ezingaqhelekanga zeeyunithi ezinkulu ze-turbo expander, libeka phambili uluhlu lwamanyathelo okusombulula iingxaki, kunye nokuqonda amanqaku omngcipheko kunye nemilinganiselo yokukhusela yokusebenza.Ngokusetyenziswa kwetekhnoloji yokususa ivanishi, iingozi ezinokubakho ezifihlakeleyo ziyapheliswa kwaye ukhuseleko lwangaphakathi lweyunithi luyaqinisekiswa.

1. amagqabantshintshi

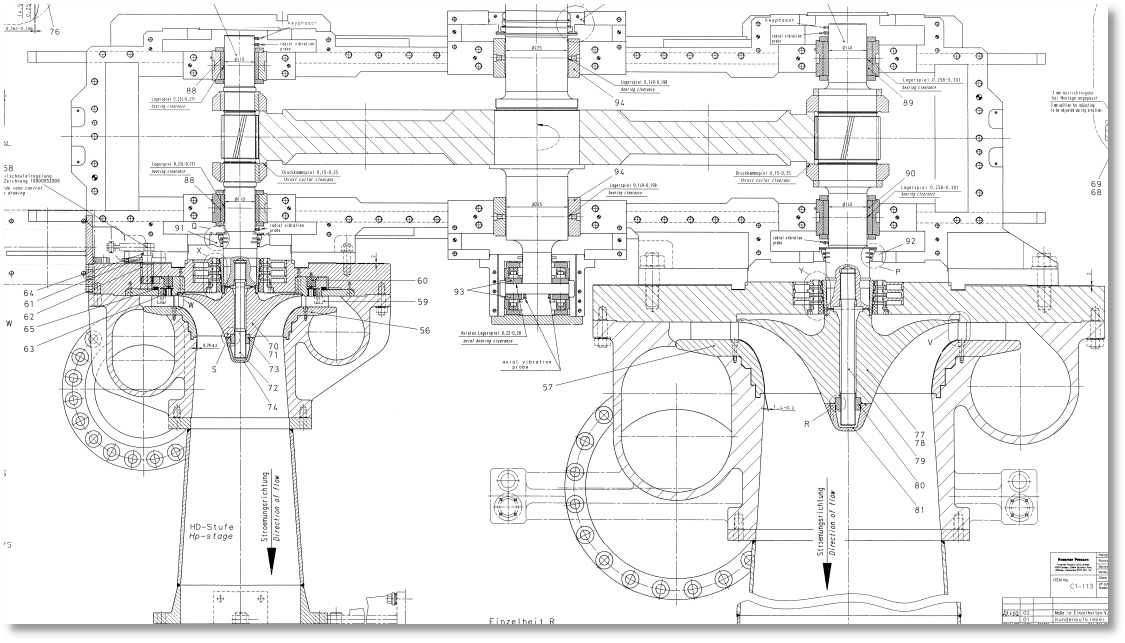

Iyunithi ye-compressor yomoya ye-60 t / isityalo se-PTA se-Yizheng Chemical Fiber Co., Ltd. ixhotyiswe ngezixhobo ezivela eJamani MAN Turbo.Iyunithi yiyunithi emithathu kwenye, apho iyunithi ye-compressor yomoya iyiyunithi ye-injini ye-multi-shaft enamanqanaba amahlanu, i-injini yomoya ejiyisayo isetyenziswa njengowona matshini wokuqhuba weyunithi yoxinzelelo lomoya, kunye ne-turbo expander. isetyenziswa njengeyunithi yoxinzelelo lomoya.Umatshini wokuqhuba oncedisayo.I-expander ye-turbo ithatha ukunyuka kwamanqanaba amabini aphezulu kunye naphantsi, nganye inezibuko zokufunxa kunye ne-exhaust port, kwaye i-impeller ithatha i-impeller yeendlela ezintathu (jonga uMfanekiso 1)

Umzobo 1 Umbono wecandelo leyunithi yokwandisa (ngasekhohlo: icala loxinzelelo oluphezulu; ekunene: icala eliphantsi loxinzelelo)

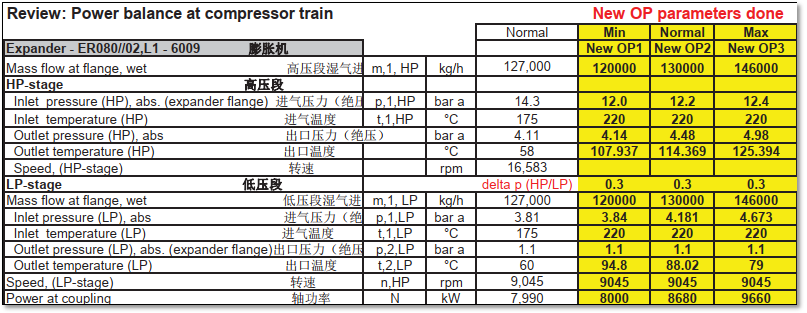

Iiparamitha eziphambili zokusebenza kwe-turbo expander zezi zilandelayo:

I-high-pressure side speed yi-16583 r / min, kunye ne-low-pressure side speed yi-9045 r / min;amandla alinganisiweyo ewonke e-expander yi-7990 KW, kwaye izinga lokuhamba li-12700-150450-kg / h;uxinzelelo lokungena luyi-1.3Mpa, kwaye uxinzelelo lwe-exhaust yi-0.003Mpa.Iqondo lokushisa elithathayo kwicala loxinzelelo oluphezulu liyi-175 ° C, kwaye iqondo lokushisa liyi-80 ° C;iqondo lokushisa lokungenisa kwicala eliphantsi loxinzelelo ngu-175 ° C, kunye nokushisa kokukhupha ngu-45 ° C;iseti yeepads ezithambekisayo zisetyenziswa kuzo zozibini iziphelo zoxinzelelo oluphezulu kunye noxinzelelo olusezantsi lweeshaft zegiya zeBearings, nganye ineepadi ezi-5, umbhobho wokungena kweoyile unokungena kwioyile ngeendlela ezimbini, kwaye ibherethi nganye inomngxuma omnye wokungena kweoyile, Amaqela ama-3 e-oyile ye-oil injection nozzles, ububanzi be-oil inlet nozzle yi-1.8mm, Kukho imingxuma ye-oyile yokubuyisela i-9 yokuthwala, kwaye phantsi kweemeko eziqhelekileyo, izibuko ezi-5 kunye neebhloko ezi-4 zisetyenziswa.Le yunithi ye-three-in-one isebenzisa indlela yokuthambisa ngenkani yonikezelo lweoyile esembindini ukusuka kwisikhululo se-oyile yokuthambisa.

2. Iingxaki kunye nabasebenzi

Kwi-2018, ukwenzela ukuhlangabezana neemfuno zokukhutshwa kwe-VOC, iyunithi entsha ye-VOC yongezwa kwisixhobo sokuphatha i-gas yomsila we-oxidation reactor, kwaye i-gas yomsila ephathwayo yayisafakwe kwi-expander.Ngenxa yokuba ityuwa yebromidi kwirhasi yokuqala yomsila ifakwe i-oxidized kubushushu obuphezulu, kukho ii-ion zebromide.Ukuze kuthintelwe i-ion ye-bromide ekujikeni kunye nokwahlula ngaphandle xa irhasi yomsila ikhula kwaye isebenze kwi-expander, iya kubangela ukubola kwe-pitting kwi-expander kunye nezixhobo ezilandelayo.Ngoko ke, kuyimfuneko ukwandisa iyunithi yokwandisa.Iqondo lokushisa lokungenisa kunye nokukhupha ukushisa kwecala loxinzelelo oluphezulu kunye necala eliphantsi loxinzelelo (jonga iThebhile 1).

Itheyibhile 1 Uluhlu lwamaqondo okushisa okusebenza kwindawo yokungena kunye nokuphuma kwe-expander ngaphambi nangemva kokuguqulwa kwe-VOC

| HAYI. | Ukutshintsha kweParameter | Inguquko yangaphambili | Emva kwenguqu |

| 1 | Uxinzelelo oluphezulu lweqondo lokushisa lomoya | 175 °C | 190 °C |

| 2 | Ubushushu obuphezulu becala lokukhupha iqondo lobushushu | 80 ℃ | 85 °C |

| 3 | Uxinzelelo oluphantsi lwecala lobushushu bomoya | 175 °C | 195 °C |

| 4 | Iqondo eliphantsi loxinzelelo lokukhupha iqondo lokushisa | 45 °C | 65 °C |

Ngaphambi kokuguqulwa kwe-VOC, iqondo lokushisa le-non-impeller side bearing kwi-low pressure end lizinzile malunga ne-80 ° C (iqondo lokushisa le-alarm lokuthwala apha liyi-110 ° C, kwaye izinga lokushisa eliphezulu liyi-120 ° C).Emva kokuba inguqu ye-VOC iqalisiwe nge-6 kaJanuwari 2019, iqondo lobushushu le-non-impeller side ephethe isiphelo soxinzelelo oluphantsi lwe-expander yenyuka ngokucothayo, kwaye iqondo lokushisa eliphezulu lalisondele kwi-120 ° C, kodwa iiparamitha zokungcangcazela azizange zitshintshe kakhulu ngeli xesha (jonga umfanekiso 2).

Umzobo we-2 Umzobo wesantya sokuhamba kwe-expander kunye ne-non-drive side shaft vibration kunye nobushushu

I-1 - i-flow line 2 - i-non-drive end line 3 - i-non-drive shaft vibration line

3. Uhlalutyo lwesizathu kunye nendlela yonyango

Emva kokujonga kunye nokuhlalutya ukuguquguquka kobushushu beebheringi ze-injini yomphunga, kunye nokuphelisa iingxaki zokubonisa isixhobo esikwisiza, ukuguquguquka kwenkqubo, ukuhanjiswa okuzinzileyo kwebrashi ye-injini yomphunga, ukuguquguquka kwesantya sezixhobo, kunye nomgangatho wamalungu, ezona zizathu ziphambili zokuguquguquka kobushushu. zezi:

3.1 Izizathu zokunyuka kweqondo lokushisa kwe-non-impeller side bearing ekupheleni koxinzelelo oluphantsi lwe-expander

3.1.1 Uhlolo lwe-disassembly lufumanise ukuba umgama phakathi kwebheringi kunye ne-shaft kunye nokucocwa kwe-meshing yamazinyo egiya yesiqhelo.Ngaphandle kwe-varnish ekrokrelwayo kwi-non-impeller side bearing surface ekupheleni koxinzelelo oluphantsi lwe-expander (jonga uMzobo 3), akukho ziphoso ezifunyenwe kwezinye iibheringi.

Umzobo 3 Umfanekiso obonakalayo we-non-drive end bearing kunye ne-kinematic pair ye-expander.

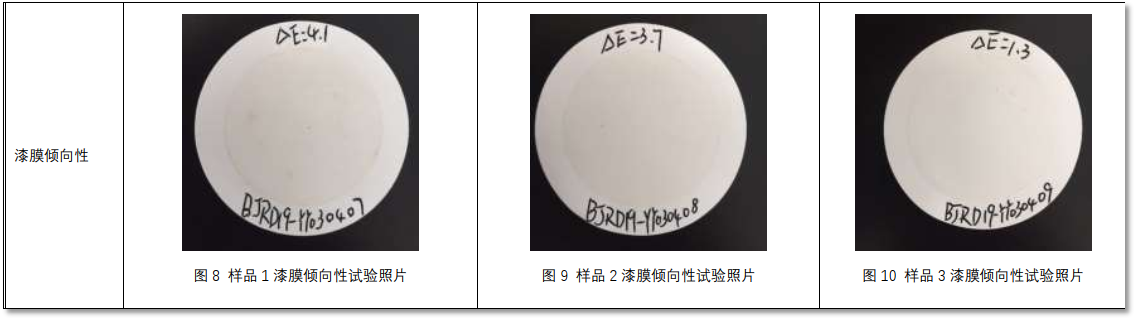

3.1.2 Ekubeni i-oyile yokuthambisa itshintshwe isithuba esingaphantsi konyaka, umgangatho we-oyile uphumelele uvavanyo phambi kokuba uqhube.Ukuze kupheliswe amathandabuzo, inkampani yathumela ioyile yokuthambisa kwinkampani yobuchwephesha ukuze ivavanywe kwaye ihlalutywe.Inkampani yobuchwephesha iqinisekisa ukuba i-attachment kwi-bearing surface yi-varnish yokuqala, i-MPC (i-varnish propensity index) (jonga umfanekiso 4)

Umzobo we-4 ingxelo yohlalutyo lobuchwephesha bokujongwa kwe-oyile ekhutshwe bubuchwephesha bokubeka iliso kwi-oyile

3.1.3 I-oyile yokuthambisa esetyenziswa kwi-expander yi-oyile ye-Shell Turbo enguNombolo ye-46 ye-turbine (i-oyile ye-mineral).Xa ioli yamaminerali ikwiqondo lokushisa eliphezulu, ioli yokuthambisa i-oxidized, kwaye iimveliso ze-oxidation ziqokelela phezu kwendawo yokuthwala i-bush ukwenza i-varnish.I-oyile yokuthambisa iminerali yenziwa ikakhulu zizinto ze-hydrocarbon, ezizinzileyo kubushushu begumbi kunye nobushushu obuphantsi.Nangona kunjalo, ukuba ezinye (kwanenani elincinci kakhulu) leemolekyuli ze-hydrocarbon zingena kwi-oxidation reactions kumaqondo obushushu aphezulu, ezinye iimolekyuli ze-hydrocarbon nazo ziya kusabela kwitsheyini, oluluphawu lwe-hydrocarbon chain reaction.

3.1.4 Amagcisa ezixhobo aqhube uphando malunga nenkxaso yequmrhu lesixhobo, uxinzelelo olubandayo lwemibhobho yokungena nokuphuma, ukufunyaniswa kokuvuza kwesixokelelwano se-oyile, kunye nokuthembeka kovavanyo lobushushu.Kwaye kwatshintshwa iseti yeebheringi ekupheleni kwe-non-drive yecala eliphantsi loxinzelelo lwe-expander, kodwa emva kokuqhuba inyanga, ubushushu buye bufikelela kwi-110 ℃, kwaye ke kukho ukuguquguquka okukhulu kwi-vibration kunye nobushushu.Uhlengahlengiso oluninzi lwenziwa ukuze kusondele iimeko zokubuyiselwa kwangaphambili, kodwa phantse ngaphandle kwesiphumo (jonga uMzobo 5).

Umfanekiso wesi-5 weTshati yezalathisi ezinxulumeneyo ukusuka nge-13 kaFebruwari ukuya kuma-29 kaMatshi

umenzi we-MAN Turbo, phantsi kweemeko zokusebenza zangoku ze-expander, ukuba umthamo womoya wokungenisa uzinzile kwi-120 t / h, amandla okukhutshwa ngu-8000kw, ngokumalunga kufuphi nomgangatho wokuqala wokukhupha amandla we-7990kw phantsi kweemeko eziqhelekileyo zokusebenza;Xa umthamo womoya uyi-1 30 t/h, amandla aphumayo angama-8680kw;ukuba umthamo womoya wokungena ngu-1 46 t/h, amandla okukhutshwa yi-9660kw.Ekubeni umsebenzi owenziwe yi-akhawunti yecala eliphantsi loxinzelelo lwesibini kwisithathu se-expander, i-low-pressure side ye-expander inokugqithiswa.Xa iqondo lokushisa lidlula i-110 ° C, ixabiso le-vibration litshintsha kakhulu, libonisa ukuba i-varnish esanda kwakhiwa phezu kwendawo ye-shaft kunye ne-bearing bush ikhutshwe ngeli xesha (jonga uMzobo 6).

Umzobo 6 Itheyibhile yebhalansi yamandla yeyunithi yokwandisa

3.2Uhlalutyo lweNkqubo yeeNgxaki ezikhoyo

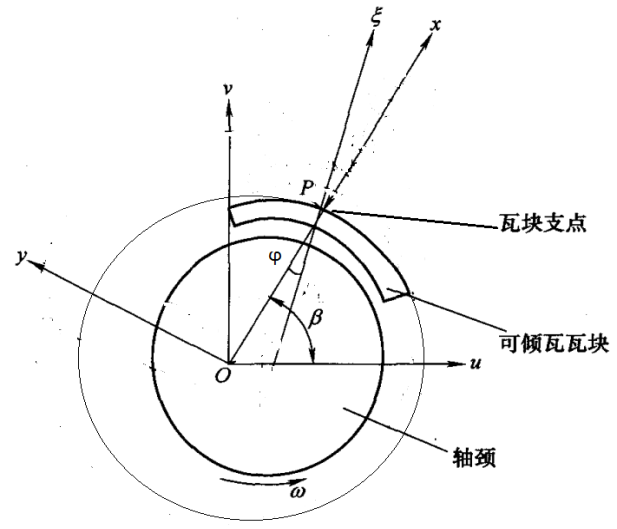

3.2.1 Njengoko kuboniswe kuMzobo 7, kunokubonwa ukuba i-angle efakiweyo phakathi kolwalathiso lwe-vibration encinci ye-fulcrum ye-tile block kunye nomgca wokulungelelanisa othe tye kwinkqubo yokulungelelanisa ngu-β, i-angle ye-swing ye-tile block φ , kunye nenkqubo yokuthwala i-tilting pad eyenziwe ngeetayile ezi-5, xa i-tile Xa i-pad iphantsi koxinzelelo lwefilimu yeoli, ekubeni i-fulcrum ye-pad ayingomzimba oqinileyo oqinileyo, indawo ye-fulcrum ye-pad emva kokuguqulwa koxinzelelo kuya ukuvelisa indawo encinci ecaleni kwendlela yokulayishwa kwangaphambili kwejometri ngenxa yokuqina kwe-fulcrum, ngaloo ndlela itshintsha ukuvela kwe-bearing clearance kunye nobukhulu befilimu ye-oyile [1] .

Umzobo.7 Ulungelelaniso lwesixokelelwano sephedi enye yokuthwala iphedi yokuthambeka

3.2.2 Inokubonwa kwi-Figure 1 ukuba i-rotor iyisakhiwo se-cantilever beam, kwaye i-impeller iyona nto iphambili yomsebenzi.Ekubeni icala le-impeller liyicala lokuqhuba, xa igesi isanda ukwenza umsebenzi, i-shaft ejikelezayo kwicala le-impeller ikwimeko efanelekileyo kwi-bush yokuzala ngenxa yempembelelo ye-gas damping, kwaye i-gap yeoli ihlala iqhelekileyo.Kwinkqubo yokudibanisa kunye nokuhambisa i-torque phakathi kweegiya ezinkulu nezincinci, ngale nto njenge-fulcrum, intshukumo yasimahla ye-radial ye-non-impeller side shaft iya kuthintelwa phantsi kweemeko zokugcwala, kwaye uxinzelelo lwayo lwefilimu yokuthambisa luphezulu kunolo lwezinye. iibheringi, okwenza le ndawo ifakwe i-lubricated Ukuqina kwefilimu kuyanda, izinga lokuhlaziywa kwefilimu yeoli liyancipha, kwaye ukushisa okukhukhulayo kuyanda, okubangela i-varnish.

3.2.3 I-varnish kwioli iveliswa kakhulu kwiifom ezintathu: i-oxidation yeoli, ioli "i-micro-combustion", kunye nokukhutshwa kwendawo yokushisa okuphezulu.I-varnish kufuneka ibangelwa "i-micro-combustion" yeoli.Inkqubo yile ilandelayo: umlinganiselo othile womoya (ngokuqhelekileyo ungaphantsi kwe-8%) uya kuchithwa kwioli yokuthambisa.Xa umda wokunyibilika ugqithisiwe, umoya ongena kwi-oyile uya kubakho kwi-oyile ngendlela yamaqamza amisiweyo.Emva kokungena kwi-bearing, uxinzelelo oluphezulu lubangela ukuba la mabhubhu agqitywe ngokukhawuleza kwe-adiabatic, kwaye ubushushu be-fluid bukhuphuka ngokukhawuleza ukuze kubangele i-adiabatic "micro-combustion" yeoli, okubangelwa yi-insolubles encinci kakhulu.Ezi zinto zinganyibilikiyo ziyi-polar kwaye zithande ukunamathela kwimigangatho yesinyithi ukwenza ivanishi.Uxinzelelo olukhulu, i-solubility ephantsi ye-insoluble matter, kwaye kulula ukucotha kunye nokuhlalisa ukwenza i-varnish.

3.2.4 Ngokuqulunqwa kwe-varnish, ubukhulu befilimu yeoli kwi-state non-free state ibanjwe yi-varnish, kwaye ngexesha elifanayo isantya sokuvuselela ifilimu yeoli siyancipha, kwaye izinga lokushisa likhuphuka kancane kancane, elinyuka. ukukhuhlana phakathi komphezulu wetyholo elithweleyo kunye ne-shaft, kunye ne-varnish edipozithiweyo ibangela Ukutshatyalaliswa kobushushu kunye nokunyuka kweqondo lokushisa kwe-oyile kukhokelela kubushushu obuphezulu behlathi.Ekugqibeleni, ijenali ikhuhla i-varnish, ebonakaliswa ngokuguquguquka okunobundlobongela kwi-shaft vibration.

3.2.5 Nangona ixabiso le-MPC yeoli ye-expander alikho phezulu, xa kukho i-varnish kwindlela yeoli yokuthambisa, ukuchithwa kunye nemvula yeengqungquthela ze-varnish kwi-oyile iyancipha ngenxa yokungakwazi ukunyibilika kweoli yokuthambisa. amasuntswana evarnish.Yinkqubo yokulinganisela eguqukayo.Xa ifikelela kwindawo egcweleyo, i-varnish iya kuxhoma kwi-bearing okanye i-bearing pad, ebangela ukuguquguquka kweqondo lokushisa kwi-bearing pad, eyona yingozi enkulu efihliweyo echaphazela ukusebenza okukhuselekileyo.Kodwa ngenxa yokuba ibambelela kwi-bearing pad, sesinye sezizathu zokunyuka kweqondo lokushisa kwi-bearing pad.

4 imilinganiselo kunye neMithatho yokuThila

Ukususa ukuqokelelwa kwe-varnish kwi-bearing kunokuqinisekisa ukuba ukuthwala kweyunithi kuqhuba kwiqondo lokushisa elilawulwayo.Ngophando kunye nonxibelelwano kunye nabavelisi abaninzi bezixhobo zokususa ivanishi, sakhetha i-Kunshan Winsonda, enesiphumo esihle sokusetyenziswa kunye nodumo lwemarike, ukuvelisa i-WVD-II electrostatic adsorption + i-resin adsorption, eyi-compound yezixhobo zokususa i-varnish ukususa ipeyinti.inwebu.

I-WVD-II yochungechunge lwezicoci zeoyile idibanisa ngokufanelekileyo itekhnoloji yokucoca i-electrostatic adsorption kunye netekhnoloji yokutshintshiselana nge-ion, ukusombulula ivanishi enyibilikisiweyo nge-resin adsorption, kunye nokusombulula ivanishi enamanzi nge-electrostatic adsorption.Le teknoloji inokunciphisa umxholo we-sludge ngexesha elifutshane , Ngexesha elifutshane leentsuku ezininzi, inkqubo ye-lubrication yasekuqaleni equlethe isixa esikhulu se-sludge / i-varnish inokubuyiselwa kwimeko engcono yokusebenza, kunye nengxaki yokunyuka okucothayo. ubushushu be-thrust bearing ebangelwa yivanishi inokusombulula.Iyakwazi ukususa ngokufanelekileyo kwaye ithintele i-sludge yeoli e-soluble kunye ne-non-soluble eyenziwa ngexesha lokusebenza okuqhelekileyo kwe-steam turbine.

Imigaqo yayo ephambili yile ilandelayo:

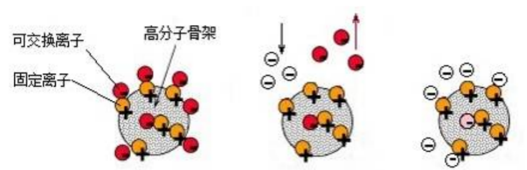

4.1 Ion exchange resin ukususa ivanishi enyibilikayo

I-resin yotshintshiselwano ye-Ion ikakhulu yenziwe ngamacandelo amabini: i-polymer skeleton kunye neqela le-ion exchange.Umgaqo we-adsorption uboniswe kuMfanekiso 8,

Umzobo 8 Umgaqo-siseko we-ion-interaction resin adsorption

Iqela lotshintshiselwano lihlulwe libe yinxalenye esisigxina kunye nenxalenye ehambayo.Inxalenye emiselweyo iboshwe kwi-matrix ye-polymer kwaye ayikwazi ukuhamba ngokukhululekile, kwaye ibe yi-ion esisigxina;inxalenye eshukumayo kunye nenxalenye esisigxina idityaniswe ngamabhondi e-ionic ukuze ibe yi-ion etshintshisanayo.Iiyoni ezisisigxina kunye neeyoni ezihambayo zineentlawulo ezichaseneyo ngokulandelelanayo.Kwihlathi elithweleyo, inxalenye ehambayo ichithwa kwii-ion ezihamba ngokukhululekileyo, ezitshintshisanayo kunye nezinye iimveliso zokuthotywa kunye nentlawulo efanayo, ukwenzela ukuba zidibanise kunye ne-ion ezisisigxina kwaye zibhengezwe ngokuqinileyo kwisiseko sokutshintshiselana.Kwiqela, ithathwa yioli, i-varnish enyibilikileyo isuswe yi-ion exchange resin adsorption.

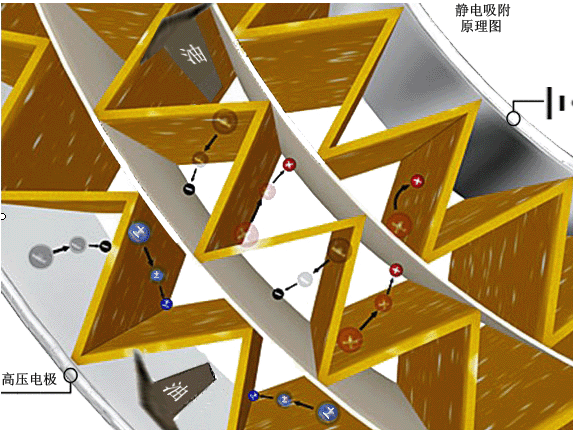

4.2 Itekhnoloji ye-electrostatic adsorption yokususa ivanishi emisiweyo

Itekhnoloji ye-electrostatic adsorption ikakhulu isebenzisa i-high-voltage generator ukuvelisa i-high-voltage electrostatic field ukuze i-polarize amasuntswana angcolisekileyo kwi-oyile ukubonisa iintlawulo ezilungileyo nezingalunganga ngokulandelelana.Iingqungquthela ezingathathi hlangothi zixinzelelwe kwaye zihanjiswe ngamaqhekeza ahlawulisiweyo, kwaye ekugqibeleni zonke iinqununu zibhengezwa kwaye zifakwe kumqokeleli (jonga uMfanekiso 9).

Umfanekiso wesi-8 Umgaqo-nkqubo we-electrostatic adsorption technology

Itekhnoloji yokucoca ioyile ye-Electrostatic inokususa zonke izinto ezingcolisa i-oyile ezinganyibilikiyo, kubandakanywa ubumdaka obuthile kunye nevanishi exhonyiweyo eveliswe ngokuthotywa kweoyile.Nangona kunjalo, izinto zesihluzo zemveli zinokususa kuphela amasuntswana amakhulu ngokuchaneka okuhambelanayo, kwaye kunzima ukususa i-submicron. ivanishi emisiweyo kwinqanaba .

Le nkqubo inokusombulula ngokupheleleyo i-varnish i-precipitated kwaye ifakwe kwi-bearing pad, ngaloo ndlela isombulula ngokupheleleyo impembelelo ye-bearing pad yeqondo lokushisa kunye nokutshintsha kwe-vibration okubangelwa yi-varnish, ukwenzela ukuba iyunithi ikwazi ukuqhuba ngokuzinzileyo ixesha elide .

5 Isiphelo

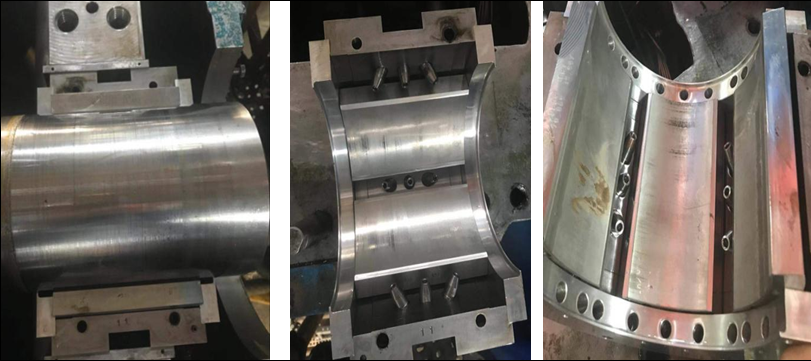

Iyunithi yokususa i-varnish ye-WSD WVD-II yasetyenziswa, kwiminyaka emibini yokuqwalaselwa kokusebenza, ubushushu obuthweleyo buhlala bugcinwe malunga ne-90 ° C, kwaye iyunithi ihlale isebenza ngokuqhelekileyo.Ifilimu yevarnish yafunyanwa (jonga umfanekiso we-10).

Umfanekiso womzimba wokuthwala i-disassembly emva kokufaka ukususwa kwe-varnish

izixhobo

iimbekiselo:

[1] uLiu Siyong, uXiao Zhonghui, uYan Zhiyong, kunye noChen Zhujie.Ukulinganisa kwamanani kunye nophando lovavanyo kwiimpawu eziguqukayo zepivot elastic kunye ne-damping pad bearings [J].Ijenali yesiTshayina yobuNjineli boomatshini, ngo-Okthobha 2014, 50(19):88.

Ixesha lokuposa: Dec-13-2022