Abstract:Indlela yokwenza kunye neengozi zokuthambisa ivanishi ye-oyile zahlalutywa. iqonga. indlela kunye nezixhobo zinefuthe elihle ekuphuculeni ukucoceka kwe-oyile kunye nokususa izinto ezingcolisayo ezintle.

Amagama angundoqo:ijini yerhasi, ivarnish yeoli yokuthambisa; uvavanyo lwe-MPC

I-injini yegesi sesinye sezixhobo eziphambili zeqonga elingaphesheya kolwandle.Isetyenziswa njengesixhobo sokuvelisa amandla kwiqonga elingaphesheya kolwandle ukuqinisekisa ukusebenza komjikelo ozinzile kunye nomjikelo omde weinjini yomoya wokuqinisekisa imveliso eqhelekileyo yeqonga elingaphesheya kolwandle.I-turbine yegesi ikwimeko yokushisa okuphezulu, uxinzelelo oluphezulu kunye nesantya esiphezulu ngexesha lokusebenza, kwaye i-varnish kulula ukuveliswa kule ndawo.Kwangaxeshanye, ngokuphuculwa komgangatho we-oyile esisiseko kwi-oyile yokuthambisa, ukukwazi ukuthambisa i-oyile yokunyibilikisa ivanishi iyancipha, ekwaqinisa ukubunjwa ngokukhawuleza kwevanishi.Ukubunjwa kwevanishi kubangela ukuqokelelana kwevanishi, umonakalo omkhulu kwisixhobo, kuya kubangela ukuhla kwe-clean, ukunyuka kwe-varnish, i-valve core adhesion yezixhobo zokusebenza azinzanga kwaye nokusilela;Ivanishi efakwe kwi-shaft, i-cooler kunye nezinye izinto ezibangela ukuguquguquka kobushushu beqondo lokutshintshiselana kobushushu be-shaft, ukukhawuleziswa kwe-oyile oxidation: ivanishi iya kuncamathela kumasuntswana aqinileyo, ithintele into yokucoca kunye nomngxuma wokupholisa, okukhokelela ekunxityweni kwezixhobo kunye nezixhobo ezingalunganga. ukuthanjiswa, i-iturbine yerhasi yasekhaya kunye nezangaphandle ukusilela kwepeyinti okungaqhelekanga ukuvalwa kwenzeka.Kweli phepha, umbhali wazisa iingxaki ezingaqhelekanga ezifana nokuchongwa kokuthambekela kwe-Huizhou 32-2 iqonga le-Solar gas turbine generator set, lixoxa ngokusetyenziswa kweiyunithi yokususa ivanishikwiyunithi yeqonga, kwaye ibonelela ngereferensi ethile kubasebenzi bolondolozo lwezixhobo kumashishini anxulumeneyo kulawulo lwezixhobo zokuthambisa ivanishi yeoli.

1 Indlela yokuqulunqa kunye nobungozi be-lubricating oil varnish

1.1 Uhlalutyo lwefilimu yeoli yokuthambisa

ivanishi i-polymer, yi-oxidation yezinto zeoli, umbala ovela kumdaka okhanyayo, omdaka ukuya kwi-tan, isizukulwana sayo sesona sizathu siphambili kukho iinkalo ezintathu.

(1) I-Oxidative kunye nokuthotywa kweemveliso zeoli: iimveliso zeoli zisetyenziswa kwikhosi.Amaqondo obushushu aphezulu, amanzi, isinyithi, kunye nomoya zonke zikhawulezisa i-oxidation, ukuvelisa i-carboxylic acid, i-ester, utywala kunye nezinye iimveliso ze-oxidation, kunye nefom ye-condensation kwi-polymer: ukongeza, i-amine antioxidant kwi-oyile kulula ukuvelisa ivanishi.

2 Iqondo lobushushu le-fluid eqhagamshelana nommandla liphezulu kakhulu, libangela ukuchithwa kwe-Rapid thermal degradation ukuvelisa i-varnish, kwaye ibambelele ngokulula kula macandelo Ukuqulunqwa kokuqokelela;ioli yokuthambisa kwimeko yoxinzelelo olubukhali kwakhona kulula ukuvelisa i-micro Combustion phenomenon, ukuvelisa ubungakanani obuncinci bezinto ezinganyibilikiyo, ezincanyathiselwe kumphezulu wesinyithi ivanishi, xa kuthelekiswa nesizukulwana sokuqala sokonakala kwe-oxidation, isizukulwana sesibini ipeyinti Isantya se-membrane siya kukhawuleza kakhulu.

(3) Ukukhutshwa kwentlantsi kuya kwenza kwakhona ivanishi, ngakumbi xa i-oyile idlula kwindawo ethile yokucoca ephucukileyo ukuze ivelise umsinga omileyo, into ekhutshwa yintlantsi yenza ukuqokelelana kwevanishi ngokulula.

1.2 Ingozi yokuthambisa ivanishi yeoli

Ukuqokelelwa kwe-varnish kwindawo yecala lokukhuhla kuya kunciphisa i-gap yefilimu ye-oyile, utshintsho lokutshatyalaliswa kobushushu Imbi, ukubola kwe-oyile yokuthambisa, okubangela ukukhuhlana kweqondo lokushisa elincedisayo ukuba liphakame kakhulu, umonakalo omkhulu kwindawo yokudibanisa;I-injini yegesi isoloko ivulekile kwaye iyeke ukusebenza, ukutshintsha kweqondo lokushisa kwe-oyile kunokwenzeka ukuba kubangele imilo yevanishi, ivanishi eyenziweyo inokubambelela ngokulula kumacandelo antsonkothileyo, anje nge-hydraulic servo valve, okukhokelela ekuvalelekeni kwevalve, ivalve. i-core bond card ifile, ukusilela kolawulo kunye nokutsiba kwezixhobo;ivanishi ikwabangela isiphumo esipholileyo sokupholisa silambatha, isicoci sivalekile, ukuthambisa okulambathayo kuyenza ibe mandundu ukunxiba kunye nokukhawuleza kwemveliso yeoli oxidation kunye nezinye iziphumo.

2 Imigangatho yokufumanisa i-Varnish tendency index

Okwangoku, indlela yokulinganisa isalathiso se-oyile ivanishi yi-ASTM D7843” yokufunyanwa kwe-membrane yokucoca i-photometric (MPC) ekusetyenzisweni kwendlela yovavanyo lwezinto ezinganyibilikiyo ngombala kwioyile ye-injini yomphunga.Iziphumo zichazwe njengepeyinti Isalathiso seMembrane ye-AE.Umgaqo wale ndlela usebenzisa inkqubo yokucoca i-vacuum Susa i-sludge kunye ne-gelatin kwimveliso yeoli kwaye uyibeke kwi-membrane yokucoca ecocekileyo Kwi-plate (i-purifier membrane aperture 0.45 p, m), sebenzisa isicoci emva kokuba ipleyiti yokucoca yomile. Film tester chromaticity ukuvavanya amaxabiso ayo MPC (AE).I-membrane yokucoca yafakwa Okukhona ufumana izinto ezininzi.Umbala obumnyama, mkhulu isalathisi sokuthambekela kwe-varnish.Xa kuphindwa

Ukunyuka okuthe gqolo kwexabiso le-MPC (AE) kufuneka kubangele abasebenzi bomphathi wezixhobo okanye abasebenzi bolondolozo bakuthathele ingqalelo.

3. Ukusetyenziswa kwe-varnish yokucoca ioli

3.1 Imo yangoku ye-oyile yokuthambisa phambi kokusebenzisa isicoci se-oyile sokususa ivanishi

I-Huizhou 32-2 iqonga lejenereyitha yerhasi iseti yiyunithi yeSolar T60,

Jonga iThebhile 1 kwiiparameters ezithile zesalathisi yeoli yokuthambisa ngaphambi kokusebenzisa i-varnish purifier.

| Itheyibhile 1 Idatha yokuvavanya i-oyile ye-turbine ngaphambi kokuhluzwa | ||

| Iprojekthi | Idatha yokucoca kwangaphambili | Ixabiso lereferensi |

| imodeli yetanki / umthamo | Umthamo we-vortex 46 # ioli / iyunithi nganye imalunga ne-1800L | / |

| Motor viscosity ye 40℃ V / (mm² s- ¹ | 45.37 | 41.4-50.6 |

| Ixabiso leasidi (kwi-KOH) w/(mg·g-¹) | 0.18 | ≤0.35 |

| Ukufuma c/(mg·L-¹) | 46 | ≤100 |

| ucoceko ISO | 23/21/11 | ≤–/16/13 |

| i-varnish propensity index / MPC | 31.5 | ≤20 |

Ukuqukunjelwa kwe-arhente yokuvavanya umntu wesithathu ngolu hlobo lulandelayo: i-varnish ephezulu yokuthambekela kwexabiso lexabiso letafile yeoli eqaqambileyo iqulethe inani elikhulu le-polar encinci ye-molecule yezinto ezingenakunyibilika, kulula ukunamathela kwiifom zetsimbi i-varnish phezu komhlaba, i-varnish iya kubangela ukungqubuzana. ubushushu besibini ukunyuka kwaye kubangele ukusilela kwesixhobo, umxholo ophezulu kakhulu we-particle unokuchaphazela uzinzo kunye nobomi benkonzo yenkqubo yecandelo elihambelanayo, i-oyile inokuqhubeka nokusebenzisa, kodwa ifuna ukusebenza okuphezulu kokucoca.Sebenzisa indawo yokususa i-varnish ukususa i-polarity kwi-solubility yeoli, kucetyiswa ukuba unciphise ixesha lokulinganisa kwaye ubeke ingqalelo ekucocekeni kunye nexabiso le-MPC kunye neziphumo zokuhlola isalathisi.Ngokuqwalasela kwindawo yezixhobo, ukungazinzi koxinzelelo lweoyile yokuthambisa kwenzeka ekusebenzeni, okuchaphazela kakhulu ukuthembeka kwenkqubo yeoli yokuthambisa elungiselelwe kunye namacandelo olawulo lwamanzi.

3.2 Umgaqo-siseko kunye nokusetyenziswa kweiyunithi yokususa ivanishi

Ngenxa yengxaki ye-varnish kwi-oyile yokuthambisa, amanye amashishini athatha amanyathelo okutshintsha ioli, kodwa umphumo awufanelekanga kwaye awukho ukhuseleko lokusingqongileyo.Ukuqinisekisa ukuba i-generator isethi Ukuthembeka, isigqibo sokulungiselela ukususwa kwe-varnish yeyunithi kunye nomsebenzi wokucoca.

Imigaqo yobugcisa yabameli abaninzi be-oyile yokucoca i-varnish yenziwa kwiThebhile yesi-2

uhlalutyo lothelekiso.

Uhlalutyo olubanzi lothelekiso lumisela intlawulo ye-adsorption + umthi wotshintshiselwano

Itekhnoloji yeLipid yokususa ivanishi kwioli.Ngovavanyo lwangempela, ndakhetha enye

I-WVD isicoci se-oyile ecocekileyo ecocekileyo, i-oyile yokuqokelela intlawulo ye-adsorption yokucoca itekhnoloji kunye nokutshintshiselana ngetekhnoloji ye-resin adsorption kwenye, kungomthi wotshintshiselwano.

Iimveliso zevarnish zihluthwe kwaye zinyibilike ngetekhnoloji ye-adsorption yentlawulo

Susa i-varnish emisiwe ekhutshwe kwioli kunye namacandelo afakwe kwifilimu.

| Itheyibhile yesi-2 Ukwahluka kweetekhnoloji ezahlukeneyo zokuthintela i-varnish | |||

| Ifom yeVarnish | Tshintshiselana ngeteknoloji yeresin | Itekhnoloji yokubiza i-adsorption | I-adsorption yentlawulo + yokutshintshiselana ngetekhnoloji yeresin |

| I-varnish echithwe kwisisombululo seoli | Ukususwa nge-resin adsorption | Ayikwazi ukususa | Ukususwa nge-resin adsorption |

| I-varnish emisiwe kwioli | Ukususwa nge-resin reverse dissolution technique | Ukususwa ngentlawulo adsorption filtration | Ukususwa ngokudibanisa intlawulo ye-adsorption filtration kunye ne-resin reverse dissolution technology |

| ivanishi eqhotyoshelwe kwisihlahla esithwalayo kunye namacandelo | Ukususwa nge-resin reverse dissolution technique | I-varnish eqhotyoshelweyo inokususwa ngokusebenzayo ngamaqhekeza ahlawulisiweyo

| I-varnish eqhotyoshelweyo isuswe ngokudibanisa iinqununu ezihlawuliweyo kunye ne-resin reverse dissolution technology |

| Uvandlakanyo olubanzi | Ukuxhomekeka kwi-resin ukususa ivanishi enyibilikayo, kwaye emva koko ukususa ivanishi enyibilikisiweyo kunye nezinto zevanishi ngomgaqo wexesha elide wokuchithwa kweoyile, ukusebenza kakuhle kuphantsi, kwaye i-resin esetyenziswayo kwixesha elizayo inzima. | Inokususa kuphela i-varnish emisiwe kwioli kunye ne-varnish eqhotyoshelwe kumacandelo, kuba umphumo we-varnish echithiweyo awufanelekanga. | Itekhnoloji yokucoca i-adsorption filtration edityaniswe netekhnoloji ye-resin adsorption ayinakusuka nje ngokukhawuleza isuse ivanishi enyibilikisiweyo, kodwa inokususa ngokukhawuleza ivanishi enqunyanyisiweyo yeoyile kunye nezinto zevanishi encanyathiselwe, ukusebenza okuphezulu, umthi ophantsi wenjongo yoboya. |

3.2.1 Ukuhlawulisa iteknoloji ye-adsorption kunye nomgaqo wokusebenza

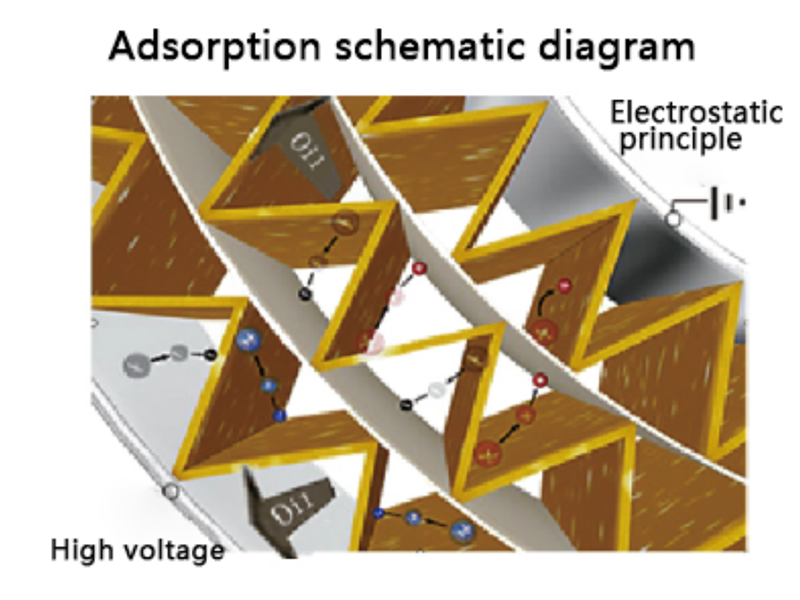

Itekhnoloji ye-adsorption yokutshaja ikakhulu isebenzisa ijenereyitha yombane ephezulu ukuvelisa amandla ombane aphezulu ongaguqukiyo, ukwenza amasuntswana ongcoliseko kwioyile ahlukaniswe kwaye abonise umbane olungileyo kunye nongalunganga ngokulandelelana, amasuntswana ombane alungileyo kunye angalunganga ajongwe ngokulandelelana phantsi kwesenzo sombane we-ultra-high. intsimi yombane I-electrodes engalunganga kunye ne-positive iqubha, kunye neengqungquthela ezingathathi hlangothi zixinzelelwe ngokuhamba kwee-particle ezihlawulisiweyo.Ekugqibeleni, zonke iinqununu zifakwe kwi-adsorbed kwaye zifakwe kumqokeleli, Kwaye ngokusebenzisa inxalenye ye-oyile ehlawulisiweyo engazange ibe nexesha lokuthatha ukuhamba, kuya Mlay ukungcola, ivanishi kunye ne-oxidation eqhotyoshelwe kwitanki yeoli, udonga lombhobho kunye namacandelo.

Zonke izinto zihlamba ibhendi ye-adsorption (jonga uMfanekiso 1).Olu buchule lunokuphumelela ekucoceni I-varnish emisiwe kunye ne-varnish eqhotyoshelwe kumacandelo, ngokuphakamisa

Ukucoceka okuphezulu nako kunempembelelo engcono.

Umgaqo weteknoloji ye-adsorption yentlawulo

Umgaqo weteknoloji ye-adsorption yentlawulo

3.2.2 Itekhnoloji yokucoca intlawulo elinganayo

Itekhnoloji yokucoca intlawulo elungeleleneyo (iBalanced Charge purification) indlela kukwahlulahlula ulwelo oluthwele amasuntswana amancinane abe ngamasebe amabini.Isebe Indlela ixhotyiswe nge-electrode yombane ophezulu ukulayisha intlawulo elungileyo kunye namasuntswana amancinci ngokulandelelana Intlawulo engalunganga: emva koko ulinganise ulwelo olubini ngamasuntswana entlawulo achaseneyo.

Udibaniso olutsha lomhlanganiselwa.Iintlawulo ezintle nezimbi zitsala omnye komnye kwaye zihlanganisene ukwenza irula elikhulu 10 intshi amasuntswana;isiphelo ngomatshini okanye isicoci se-centrifugal I-intshi yokwanda kwento encinci.

3.2.3 Ukutshintshiselana ngetekhnoloji ye-resin adsorption

Akunakwenzeka ukuba iimveliso ze-varnish ezinyibilikileyo zithembele kwi-teknoloji ye-adsorption yentlawulo

ukuhlamba.Isixhobo se-resin esilungiselelwe ngokukodwa yimveliso yevanishi enyibilikisiweyo (ekwabizwa ngokuba yi-lacquer film embryo) inika isicoci esiphakathi ngokusondelelana okuphezulu, usebenzisa i-resin Amaqela asisiseko atyebileyo kwizinto ze-adsorption angabhengeza zonke iintlobo zemveliso yokuthotywa kakuhle kakhulu.Ngaloo ndlela inezinga eliphezulu lokususwa kweemveliso zevarnish.I-resin adsorption material Ukuzinza kwezinto ezilungileyo, ukumelana nobushushu obuphezulu, ukusetyenziswa akuyi kuba neemveliso zokuthotywa kunye nokuwa Izinto zingena kwioli.Ukongezelela, ukusetyenziswa kwe-resin reverse dissolution technology (thembela emthini Emva kokuba i-lipid isusa ifilimu echithwe kwioli, ifilimu emisiweyo kwioli kwaye ifakwe kwi-varnish kumacandelo iya kuphinda idibanise i-oyile ibe yincibilikisiwe. i-varnish, Emva koko isuswe nge-resin adsorption), ioli kwi-varnish ye-suspension state kwaye iqhotyoshelwe Kumacandelo e-varnish nayo inefuthe elithile lokususa.

3.2.4 Isiphumo esikhethekileyo sokusetyenziswa kokususa isicoci se-oyile ivanishi

Nge-WVD i-varnish ecacileyo yokucoca ioli kwi-platform ye-32-2 i-Solar Iyunithi ye-T60 ihlanjululwe umjikelezo we-intanethi malunga neentsuku ze-10.Kwisisombululo se-oyile ecocekileyo Idatha yovavanyo lweSampuli iboniswe kwiThebhile yesi-3.

| Itheyibhile 3 Idatha yokuvavanya i-oyile ye-turbine emva kokuhluzwa | ||

| Iprojekthi | Idatha yokucoca kwangaphambili | Ixabiso lereferensi |

| imodeli yetanki / umthamo | Umthamo we-vortex 46 # ioli / iyunithi nganye imalunga ne-1800L | / |

| Motor viscosity ye 40℃ V / (mm² s- ¹ | 45.43 | 41.4-50.6 |

| Ixabiso leasidi (kwi-KOH) w/(mg·g-¹) | 0.12 | ≤0.35 |

| Ukufuma c/(mg·L-¹) | 55 | ≤100 |

| ucoceko ISO | 15/13/9 | ≤–/16/13 |

| MPC | 4.4 | ≤20 |

Ifunyenwe nge-arhente yokuvavanya i-oyile yesithathu. Emva kokuhlanjululwa, ukuthambekela kunye nococeko lwesalathisi sefilimu ngaphambi kokucoca kucacile Ukuphuculwa, ixabiso le-asidi nalo lehla kakhulu;nangona amanzi anyuswe kancinci, kodwa Ukuqwalasela ukuba imposiso yobhaqo kunye nezinye izinto zisengaphakathi kuluhlu olufanelekileyo, ngoko ke ayithathwa njengesiseko soVavanyo lwereferensi;zonke ezinye izalathisi ziqhelekile, kwaye isiphelo sovavanyo sifanelekile.Ngexesha elifanayo elicacileyo Uxinzelelo lokulawula ioli yokuthambisa aluzinzile ngexesha lokusebenza kwe-varnish yokucoca Uphuculo oluphawulekayo, kwaye umphumo uyabonakala.

4 Ukuqukumbela

Indlela yokudibanisa intlawulo ye-adsorption kunye nesixhobo sokutshintshiselana nge-resin inokuphucula ngokubonakalayo ukuthambekela kwe-oyile ye-iturbine yokuthambisa umgangatho kunye nezikhombisi zesidanga songcoliseko.Faka iyunithi ye-Solar T60 kwi-platform ye-32-2 emva kokusebenzisa i-varnish yokucoca ioli yokucoca kunye nochungechunge lwe-WVD.Iyunithi yokuthambisa i-oyile ivanishi yezalathi zokuthambekela kunye nokucoceka kwaphuculwa kwaye kwabuyiselwa kuluhlu olufanelekileyo, yafumana umphumo oyifunayo, ukuthintela ukubunjwa kwevanishi, enye into ebonakalayo kunye neekhemikhali. umcimbi wokungazinzi kwamandla nawo uye wapheliswa, ukuqinisekisa ukusebenza okuzinzile kweyunithi.Ukongezelela, iyunithi yokususa i-varnish iqhuba ngokuzinzile kwindawo enzima, umphumo uyabonakala, iindleko zokusetyenziswa kwexesha elide ziphantsi, zisebenza kakuhle.

Ixesha lokuposa: Mar-15-2023